Summary

- Learn about key trends and challenges shaping today’s trucking industry

- Hear expert insights and practical takeaways from experienced industry voices

- Get answers to real-world questions during a live audience Q&A session

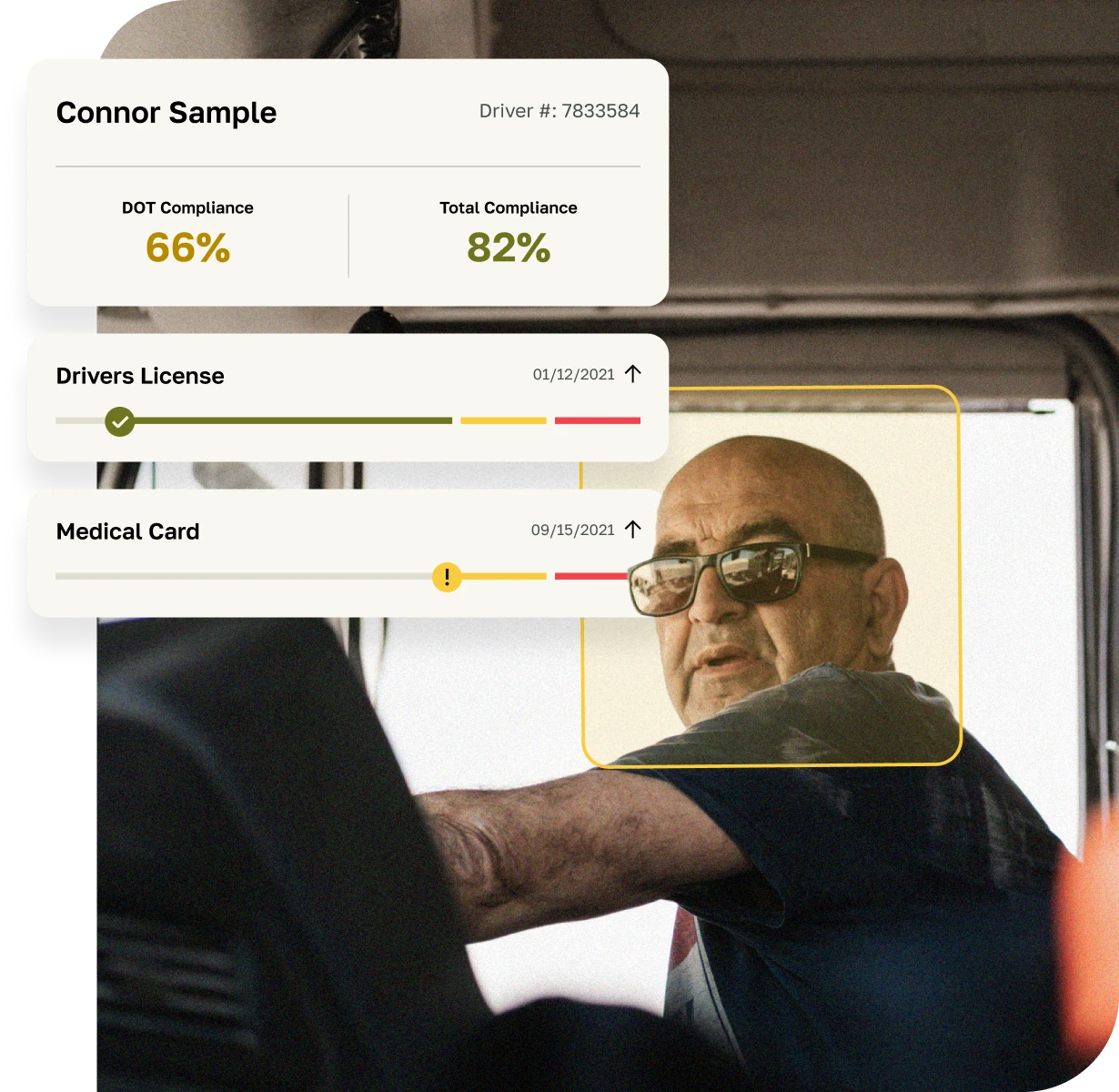

Hello, and welcome to today’s HDT editorial webinar presented by bestpass. Best pass how to drive down the rising costs of running a fleet. I’m David Cullen business in Washington editor of heavy duty Trucking and I’m your moderator for today’s panel presentation. I encourage you to submit questions during the webinar. We’ll try to answer those in the Q&A session. If we do not get to your question. You will be contacted by email with a response after the event. Are two guest speakers will share their expertise on how to drive down operating costs by staying on top of several specific areas. These are few optimization and compliance route optimization. Toll management and through the general benefits of adopting new technologies. With our panel former. I’ll be throwing questions to our our two speakers and they may also discuss. Or ask questions among themselves as we go along. Also anyone with a question for our speakers may enter it using the writing feature on the dashboard. These will be addressed during the Q&A session. our speakers today are Brian Antonella Who is senior Vice President we operations for Fleet advantage and Brent Ellis vice president of Business Systems and processes for Decker Truck Lines. Our next if you take a look our next six slides we’ll present takeaways with bullet point provided by Brian and Brent respectively while speaking they they may reference points presented on their slides. Now, I’ll start with the question for both speakers. What is your general perspective on Rising operating costs and which right now are being in fluid influenced the most by inflation a Brian. Would you like to go first, please? Sure. Sure, David. Thanks for having us. Everybody has seen the impact of rising costs over the past several years. It it really seemed for a while. Like they were directly correlated to supply chain challenges that that we saw on the manufacturing of new assets and people keeping assets longer. But there’s been a there’s been a shift we’ve seen the average age of equipment continuing to increase we’ve seen certain key components as a challenge. And we’ve seen labor shift, right? It’s we’ve seen a certain amount of drivers start to leave the industry and all those compounding are making it very challenging for someone to run a p&l in this industry for probably, you know, 20 years. It was you added two and a half or three percent to you annual budget. You were able to manage that you could understand the channel changes that happened year over year and over the past three years that’s really all been thrown out and one of the things that we’re doing and to work with our customers is to make sure that we reset the new Baseline, right? We understand what it’s gonna look like going forward and what your costs look like with your new drivers your training costs being added in as well as the shift in your average age of equipment that’s happened over the past few years. All right. Thanks. Thanks very much, Brian and Brent your thoughts on the current impact of inflation versus historic record if you will. Well, I wouldn’t I would agree with what Brian said I think from an equipment standpoint, you know, obviously equipment costs are not are not going down and and are not going to but on the other side of that from a technology perspective. the technology space has become flooded in the last three to five years with new vendors new, you know, everybody has a an idea of what’s needed and everybody’s trying to capitalize on that because they’re going going up as much as as equipment costs. As Brian mentioned with the workforce, you know, we’re seeing drivers leave the leave the industry, but we’re also seeing a shift in in driver thinking, you know, a lot of the a lot of the drivers now they want more home time. They don’t they don’t want to be gone for weeks at a time. They want to be home. Weekly and and some you know multiple times in a week. So that’s that’s caused a big shift as well. All right. Thanks very much Brent. and Brian if we could turn to your your points about route optimization on slide four that is always sound sounds like a straightforward discipline, you know, you have routes and you want to optimize them. But you you present right optimization in a dynamic light you talk about not having a static plan but reacting to changes Outside The Fleets controls. Getting drivers to buy in and most compelling planning for disruption of you know, that’s the one that interests you the most how do you actually plan for disruption and to enable better route optimization? Well, I think this question is really timely think about what Brenda said, right? There’s all there’s all these new technologies that are coming out. There’s different ways to track your vehicles to forecast when they’re going to arrive, right? And there’s there’s all this new entrance into that space. So we’re talking about right optimization, you know in many Industries. It used to be very stagnant. You have an event whether it was quarterly or biannually, right and you would look at Hey, how do I get back to as close as the targets? Whether it’s a x number of deliveries per hour or X number of cases per delivery, whatever it was. But now that what we’re seeing is we have more visibility into what the driver’s doing how the truck reacting what are the key challenges the trucks are having right? So with all that new data that we’re bringing in and I’d love to get Brent start on it after right with all that new data that we’re bringing. How do we manage it? So I think it’s about trying to empower your local teams to get prepared for the challenges that they’re seeing. Not just a overarching corporate Mandate of you’re going to do this quarterly, right? You have to react to your customers. You have to understand what’s happening. You need to be able to take in that data and make decisions quickly right not. Hey next quarter when they come out. We’ll take a look at it. Right and when you think about playing for disruption You know, whether people had a plan for a work stoppage or the pandemic or we’ve seen some environmental events that have happened thinking about how you’re going to move equipment around your network. If you had a event that hit a Southern state a hurricane a tornado in the midwest. How would you react what would that look like who were the key people that would immediately become engaged when that happened, right? How is that going to affect the rest of your network? You have the ability to leverage third parties as you pull through a dress and affected area. and I think many of us had hurricane preparedness plans over the years or you know driver work stoppage plans over the year, but I think what we saw during the pandemic is Not only can this happen. It’s going to look different. We’re going to have large amount of people come in and out of the workforce and we need to be prepared for it. So I think it’s less about having a hurricane preparedness plan. Is having a challenged work environment area right and having the whole company prepared to move forward. But I’d love to hear Prince thoughts on integrating the new technology and there you hit on a bunch of them right used to be what we referenced as GPS and now it is everything from breakdown tracking to predictive maintenance to trailer tracking to load stability to temperature monitoring. All those things are factor. So Brenda, I’d love to hear your thoughts on those. Please feel free to go ahead friend. And you’re you’re absolutely right so much. I’m sorry, dude. You’re absolutely right Brian. There’s so much data available. Now. We’re almost in Overload at times. And I think what we’ve tried to do here is is avoid the paralysis by analysis. We try to identify. One hour goals are and what data do we need to manage to that? Um, it’s really easy to get lost in the in the the nuances and the minutiae of the data that is out there. And try to make use of all of it, but I think the biggest thing is it’s a it’s a shift in thinking from like you mentioned a disaster plan, you know a hurricane a snowstorm a tornado anything like that to just a complete disruption in the day-to-day. I think the pandemic taught us that you know, there are there are things worse than a storm that you know affects us for a few days. And we also learned that you know by and large the customers want to cooperate and they want to they want to get us in and out and get us loaded and unloaded as quickly as possible, but We we seem to forget at times that they’re facing the same issues. We are with the labor shortage and and supply chain issues and all that. So, I think the biggest thing there is just to identify what the goals are and what day is needed to manage to that. To prevent just getting lost in data. All right. Thanks Brenton. I’m slide eight Grant you you discuss optimizing. routes as well specifically you mentioned adding in a scale bypass system. Can you speak a little bit to what that does for Decker? Sure, we’ve we’ve used scale bypass for a number of years. Recently within the last couple of years. We switched to drive wise as our as our bypass provider. And they’ve been phenomenal. there are shared sites which DriveWise shares with other other providers in their exclusive sites and what we saw when we we did a 30-day trial plan where they just pulled data and and basically let their system running the background and still using our own provider as the as the primary but then we we took a look at that data after 30 days and realized that we were missing out on a lot of scale bypasses. And you don’t think much about the cost of a driver just you know, pulling off and and driving through the scales, but overall from a time-saving perspective and a cost saving perspective. It’s it’s huge. You know if a driver is doing 65 on the interstate it when they pull into a scale it takes a while to get through the scale and then to get back up to speed if they’re you know when they come out the other side. so that’s that’s been huge for us and the hour provider Drive wise they also, you know, they offer the safety plus feature that gives drivers warning of Hazard areas like rollovers Steve grades that sort of thing an audible. chime on their on their ELD device and the you know in a full screen warning that that tells them what’s what’s coming up ahead. So it’s been huge for us and we’re currently in the process of implementing A dispatch optimization. software to Manhattan Associates, it’s driver and load and drop and Swap and it it takes a 30,000 foot view of all available loads in the system and all tractors and trailers and drivers and hours of service and everything that could possibly come into play and and it makes a recommendation of you know, your top five. driver tractor combinations match to a load or vice versa top five loads for for a driver tractor combination With that, you know, it’s configurable to to work toward reducing deadhead or you know any number of goals that you want to set we look to be live with that probably early to mid-march and I think that’s going to be huge for us as well. But anything you can do to to reduce miles driven, you know, special non-productive miles your dad head and that sort of thing. It’s it’s fantastic, you know and driving down costs and it’s it’s really not that difficult to do. And Branch a follow-up to that. As also on Slide Five you talk about sorry wrong. Sorry one second. It’s a slight eight you talk about the tension cost control. It’s it seems that it’s one thing reduce miles, but you want to gain time and does does having that an emphasis on detention cost the besides getting the the money back that you’re you’re owed for holding up your Fleet. Does that provide incentive for shippers to not detain you so much which gained with gain you time? To an extent it does, you know, you mentioned getting back the money and and to be quite honest the detention rates that most shippers pay don’t come close to offsetting the cost of detention. you know if the with the driver Market what it is now drivers want to drive they don’t want to sit. They don’t make money sitting still. Um, so we want to keep them moving and keep them happy but we also you know if they are detained and they’re going to be compensated for that and we do try to recoup the cost at least part of the cost of the driver compensation for detention, but by and large, you know, it’s it’s not a detention is not an issue that’s specific to to Decker or to any Fleet. It’s it’s impacting us all. um but you know, it’s even past the driver pay in the driver satisfaction piece, you know, if a driver if you’ve got a driver planned on their next load and they end up being held up three hours past what they should have been to be unloaded at their current stop then. You know that that can push that next the next pickup weight which can have a it’s kind of a Snowball Effect. We’re continues to to affect things for days after and we want to avoid that as well. But detention is a real is a real cost to every carrier out there and you know again going back to the labor shortage that a lot of shippers are seeing and we’re all seeing it. It’s it’s not getting better. It’s getting worse. So, you know, it’s something we have to continually keep an eye on and and monitor and and manage. Sounds good. Thanks Brent. And going over to you Brian on. Slide Five you talk about technology for asset management and predictive modeling. And from what I when I read There It suggests to me that those those two may go hand in glove. Do you see these? Do you see it that way? And if so, there’s a fleet need to roll both out at the same time or can you start with the predictive and then from that game insights into asset management or just way around? Yeah, great question. So yeah, I actually think it is the other way around right? So when you think about how you’re gonna set a life cycle I go back to that comment. I made earlier where you know we were so we were in such a smooth pattern for vehicle acquisition for 20 plus years right that people felt very comfortable. Hey, we keep our trucks or trailers five year seven years nine years, whatever the number was. And they have their operating plan built around the increases that they would see and they were able to buy trucks in a uniformed approach to the cost didn’t change that much. So a lot of people didn’t put a lot of effort into capturing incoming data whether it was MPG data or whether it was the M&R data from your maintenance provider. So as you think about it, you need to have the root information to be able to make good decisions. So we want to make sure we understand first of all is that we’re capturing all the costs associated with the trucks and trailers or understanding by component level right down to the vmrs code level so that we know which components are making it to the end of the assets life. And which ones are failing before and how that cost impacts it. We want to understand the mpg and you know, what what has happened with these ghg mandates over the last 10 years and how it fuel is improved and then at one point in the life cycle that we start to get fueled degradation right where towards the end of its life. We start getting lower performing MPG results. When you gather that data and you think about it from a full life cycle management of the asset, you can then start doing the predictive modeling right? You can understand exactly at what point an asset is costing you more money that it would be to replace it. Right we call that the Tipping Point because it would you know, the MNR cost in the fuel MPG increases that you see outrun any additional cost of capitalizing the asset, right? But making sure that you have that information is crucial understanding that Fleet cost doesn’t happen year over year by accident. It’s actually very predictable. You can watch the curve you come into year one and you might have a repair and maintenance cost of you know, two to two and a half cents per mile. As it ages through year three year five you can get up to that seven eight nine cents a mile. And after you go past year five and somewhere on five hundred thousand miles you start to see major repairs fall in right? So you start to see the cost of that asset s group escalate dramatically and you start to see different locations seeing costs and sporadic. It’s not even across the board. Right? You’ll one location. We’ll see of 20 or 30 percent increase it becomes very difficult to budget but it’s very important that you have that information. So when you do predictive modeling to say what should my asset life cycle be we’ve fallen out of whack over the last two or three years to get back in. This is how many trucks I should buy. This is how many trailers I should buy and if you can get down to the vmrs code level we can actually start making Speck enhancements that reduces your cost going forward. So, yes, they go together, but it’s about having that base understanding in the data coming in to be able to put it into a predictive modeling format to where you can say. Hey, here’s how this is going to affect not just my Capital number, but my Capital number and my Opex number over the next three five seven years as you set your life cycle. All right, and that that’s a you know, that’s a that’s the big picture but drilling down for a moment Brian. I I know she mentioned vmrs coding and that’s been around a long time and I’ve always regarded as kind of foundational data that that you the kind of foundational data that you need to drive all these software programs, but I’m not sure how familiar everyone today is with vmrs. Would you mind taking a slight detour to explain what the Mrs stands for and what and how it’s applied, you know in a brief way if possible. Sure, so vmrs code is the code that is assigned to each system within a truck right and or a trailer. So if you think about it brake system is system 13. So all the costs associated with breaks will get captured under 13. As you go up into the 40s, you move into power plant, right 44 45 different power plants and when you can take your maintenance data, whether using a third party, you’re using your own technicians and as they’re doing repairs they say, okay. I’m working on system number 13. I’m working on breaks and I’m applying a part cost of $500 and I have a labor cost of 250 when you can gather that data by vmrs code. Over the life of the vehicle. You can not only get very predictive on what it’s going to be the next year because you can understand how many brake jobs that you’re gonna have to do over the life cycle the vehicle you can use that to Target when you should replace the vehicle before key components are going to fail but you can also use those codes to spec pieces of equipment better. Right? So when you go into buying a new trucks, you don’t say I am gonna order the same truck. I did last year. No we should go in and look at do I have brakes that are a challenge do I have an automated transmission that gave me additional cost versus right a full automatic transmission, right and to be able to make those decisions in your life cycle is critical to making sure you buy the truck the correct way you maintain it the correct way and you set the correct budget a lot of what we’re hearing now from our customers is my costs are up. And I just want to make sure that we’re spending the money in the right spot. If you don’t have that data, if you don’t understand where it’s going and how far you’ve drifted off your traditional life cycle, you’re never going to have a high confidence level that your year over year. Apex numbers are going to be consistent. And that to your rest of your organization, you’re going to be able to share that information with them and have them have confidence in you that you’re managing their Fleet correctly, right? So it the Mrs codes they are codes on trucks that allow you to Target certain areas. And as you’re doing maintenance apply cost so that you can understand what part of the truck or trailer is driving the cost. Okay. Thanks Brian. Do you have any thoughts on that the impact of Of life cycle costing for for cost control obviously, but why do it at that to that degree? I think everything Brian said was spot on you know, the the number one dependence in our industry is the equipment. So, you know if the equipment is if it’s performing below standard, if you’re spending more keeping it on the road, then you’re then you’re making profit with it. Then it’s it’s definitely an issue. So, you know here at Decker. We we tend to keep our our Fleet around the three three and a half year mark. So, you know, we’ve we’ve looked at the data and determined that that’s kind of where the the profitability starts to taper off. So, you know, it’s a lot of expense to buy those new those new tractors, but it’s also a lot of expense to keep the old ones pieced together. And also, you know, you don’t want to put your drivers out in something. That’s that’s not Dependable that’s gonna cause issues and So yeah, I think he spot on with everything he mentioned. Okay. Thanks very much, Brett and swing over to tolls Brent. You mentioned on slide seven using electronic toll management. Can you can you delve into the benefits of this technology and when Decker started using it and also how customizable is is the system you use? You know we again we had we had another provider for a number of years recently made a switch probably a year and a half ago to best pass. Best pass has been phenomenal. We have all the data we need I mean we can see, you know, every every total entrance every total exit one of the biggest advantages in my mind is You know using GPS data they can tell exactly where a tractor entered a toll a toll road and where they exited. We all know that you know things happen and for whatever reason maybe that particular state says that you entered at this spot and left at this spot and you owe x amount, but that’s that’s not accurate and best pass jumps on that grenade and and you know, they they take that up with the with the state so that we don’t have to take take the burden off the the carrier to manage that they’ve been a great partner. Obviously, you know, you want to if possible avoid the toll roads as much as possible, but it’s it’s a necessary evil out there. So it’s it’s been huge for us the move to best pass couldn’t couldn’t say enough good things about All right. Sounds great. See Brian any experience with electronic toll management among your Fleet clients. Yeah, I I agree with with Brent right and I’d actually go back to his previous comment and sort of connected to so earlier. He talked about managing your scales. And he talked about, you know, an asset optimization. He talked about keep drivers moving and keeping them, you know, productive and moving down the road as we’ve gone through this. Whether to drive or shortage or shift in how they approach the job, right? All we’re really trying to do is get minutes back for the drivers. We’re trying to add miles in and whether it’s the managing scales managing tolls, you know several of our customers we’ve even done gone to the extent of managing how we fuel their trucks at night. And if you’re returning home, do you want your driver filling up the truck for 20 or 30 minutes of this day and filling up the what windshield washer fluid or do you want to get him back with his little time as possible? But then provide that additional service that I have to do it, but I agree with Brent. I think it’s all about managing the minutes of the drivers and adding more product productive time into their day and take out some of those things that we can manage whether it’s from a corporate standpoint or from a you know, a terminal management standpoint. Okay. Thanks, Brian and speaking of speaking of drivers Brent you note on slide seven that Decker uses a few optimization fuel optimization system and that includes scoring drivers on the on their compliance and then the drivers can receive a monthly bonus based on their score. Can you talk a little bit about how that was set up and how how it was greeted by drivers and as it grown in popularity and the maybe the impact it’s had on your fuel spend, of course. Sure, again, previously. We had a we had another provider. We we made a shift last year to to Manhattan fuel in route the provider we had previously. It did what it was designed to do Manhattan takes it a step further. They use numerous algorithms speaking of tolls. It takes toll roads into considerations along the route that sort of thing. It looks at driver’s hours of service on time delivery. It takes in into account numerous aspects of the load. It even looks at average fueling time at a particular stop at a particular time of day. And basically what it allows us to do is is it will it will determine let’s say there’s there’s route a and Route B to get to the same location throughout a has a toll road. That’s you know, it’s a 95 Dollar Coal route B doesn’t have the toll the fuel is more expensive and it looks at excuse me the entire the entire trip to determine what’s the lowest possible cost for fuel within within our specific Network? We’re able to set minimum minimum purchase requirements where you know, we don’t want to stop the driver over 50 miles to get fuel. So, you know minimum purchase of 50 60 gallons, whatever the case may be minimum fuel level so that we don’t have the drivers going below a certain amount, especially in the winter. Things like that, but it will you know, it may recommend. A toll road over a non toll road because you can you know, there’s a substantial fuel savings by taking the toll route and paying the toll versus missing the toll and paying a little more for fuel or vice versa. um drivers were not they were skeptical in the beginning when we started to make the change. You know, they had a lot of the drivers hadn’t been held to the standard that that we kind of put on them during that change in that what the true definition of compliance basically. it took it took a minute for them to get past the skepticism and and but you know, I think by and large the most of them realize now that you know, it’s it’s not only is it saving the company money and fuel which they’re you know, their compensated through a bonus program. It also has productivity back to their day. They’re not You know, they’re not stopping as often and they’re they’re stopping it better locations and they’re not they’re not wasting time looking for a place to get fuel because the the fuel solution is generated and sent to them when the load is dispatched. So they know exactly where they’re fueling from from the day they get the dispatch for the load. So it’s it’s been huge for us and and cost savings is substantial. You know, it’s we’ve we’ve looked at certain Lanes where? Based on the cost the fuel cost for from our old system to the new, you know, there are times when we say three to four hundred dollars in fuel costs on a particular route. So it’s it’s made a real impact. That is substantial. Thanks. Brian. Brian needs thought yourself on having an MPG, you know driver’s scorecard of program with the bonuses built in are those I know you’re many of your clients are privately to those common among privately. No, I absolutely because you Brent has talked about how Key decisions. It’s great. If you can automate them and force them down a certain route, but in many cases in the private fleet World, they may be making stops. They may not understand when they’re routing. No stops what the impact of either taking a toll road or going a little farther, but being able to move a little quicker what those impacts are. So one of the best things and that you can do is to involve the driver in it say hey, we’re gonna give you a little bit of The Upside that we’re going to recognize Right, but the one thing I’d say. Where I’ve seen it as a negative is if you’re not consistent with it. If you roll out a program and you say hey every month, we’re going to review MPGs or outer route miles or whatever the metric is that the organization chooses to Target to drive the the increase or the reduced cost and fuel. You have to be consistent. I don’t know how many times I’ve walked into facilities where they say. Oh, yeah. We used to have a fuel program. This is where it was. Yeah. We got that bonus for a few months and then it stopped. If you take that approach your drivers quickly disengage and it’s very difficult to get them to buy back into the process. So I think it works I think you know allowing them to reap the benefit of the reduced cost and a bonus program works, but you need to be consistent when you roll it out and if if you’re not gonna be consistent you’re gonna be have challenges rolling out a similar program or a like program in the future. All right and stick with you Brian if we go over to slide six you talk about different kind of scorecard. And and this is new to me and the mission score card that helps determine the optimum procurement and Disposal strategy for for individual trucks. Can you can you speak to that give us a understanding of how that works and process importantly, how do you get something like that started in your Fleet? Sure. So, um, you know something we never would have thought about 10 years ago, even 10 years ago when we talked about being green or being environmentally friendly it was about buying newer equipment getting the old trucks off the road, right but as we’ve moved through and and we’ve gone and people in organizations align their core values around reducing greenhouse gases the question became how do you measure it and how do we measure the decisions that we’ve made whether was to update a fleet or go to alternative fuel? And what does that look like? And how do you project that? Right? So one of the things that we do for a lot of our customers is we do what we call on a mission scorecard. Understanding the amount of fuel that they burn. Assigning the greenhouse gas associated with the fuel that’s going to burn and as we make Acquisitions as we lower the fleet age as we track the improved MPG from the greenhouse gas emissions targets that have been put out. We should we show when we quantify how much Fewer missions, we’ve put into the air, right and for many of our customers that is you know, we we track M&R costs for our customers we track MPG costs, but it’s amazing that that scorecard is now being the one that’s being requested by the c-suite. They want to say with our you know, reduce life cycle with our Capital purchase. Are we doing the right thing? And how do we prove that and so understanding how changing your average age your vehicles requiring new vehicles moving to alternative fuels how that’s going to affect your overall output is important and you know, it’s it’s a fairly simple calculation. But once again we talked about grounding in data, you need to understand your MPG. You need to understand how many how many how much fuel you’re burning right and you need to put it into a format and be able to track it and not only track it but forecast it. sorry, and now maybe a little early in the game for this but how might that tool be used to help assess whether a fleet should consider adopting some some electric trucks and Battery electric trucks. that they’re supposedly zero emissions, but how does that does that make it? A discussion of an emission scorecard or does it just Trump any any of that the electric vehicle? Oh, no, no great question. And you know we’ve worked with a lot of our partners to figure out what that’s going to look like, you know, everybody knows that while the tailpipe emissions may be zero out of an electric vehicle right? There are the emissions that are created within the process whether it’s you know producing the electricity that’s going to charge the battery. It creating the battery itself, right? There are. Industry experts that have referenced a 25% increase in greenhouse gas emissions to build an electric vehicle. And I’m not here to be negative or positive on electric vehicles, but I’m here to say is when you think about what your net output to the environment is. We need to include the emissions. Increase or equal approach to Emissions on the scorecard for that when we make those switches, right? So You know one of the customers we ran the evaluation for to outrun a diesel truck. It took him about three years of running an electric. to make sure to pass that emissions output of a diesel right to be up to to be under so yeah, there’s a lot of it’s gonna evolve but it’s important that we’re measuring that when these when our customers have it as one of their top two or three goals you hear, you know emissions free by 20 30 emissions free by 240 until we start counting and understanding what that looks like and how different types of vehicles are gonna play in that. I don’t think we can really say we’re headed in the right direction. I see what you mean that makes it that makes perfect sense Brian and Brent moving over to you on slide 9 you talk about taking a connected Fleet approach and when I hear the term connective Fleet, I think about telematics and integration and but I wanted you to you know, tell us a little bit about how Decker approaches it, you know and how you work with vendors and and I guess what comes front of mind to me is how do you integrate all this so that you benefit from it without being overwhelmed by it? Sure. It’s a I will say overwhelmed is a good word to use there because the as I mentioned earlier the amount of data that’s available in itself can be overwhelming but you know having the having that connection to the driver and to the truck and even the trailer at any given time, you know, we’re we’re about 60% reefer. So, you know, we we know at any given time the temperature inside that inside that reefer unit and what you know, that’s monitored. We get notifications if it’s outside of a certain range. Brian mentioned early on you know, the amount of visibility we have into the driver’s world and and what they’re dealing with real time almost. We have right now I manage about. Fort I believe it’s 14 software systems 14 different vendor accounts that are vendors that we use probably 85% of those are integrated to eat not only to each other but to our TMS as well. They’re all integrated to our TMS but some integrated with each other. in there’s so much so much data available as I keep saying that but it’s you know, everything everything that’s within the ECM of the truck we have access to We have a couple of providers who who they do some analytics for us and they’ve built some custom algorithms and custom things that live within a within a portal. They give us instant access to basically anything we want to see outside of that. We’ve been able to to leverage things like power bi Tableau those sort of things to pull data from multiple systems and mesh that together to create dashboards and reports. You know, obviously not just in the operations group but across the company and try to give each department of you what’s important to them, you know, and and that in itself can be a challenge of times because depending on the situation, you know. accounting wants to see these numbers but operations realistically you have to have the it has to be at this number for whatever reason so, you know, there’s sometimes you get the referee the compromise there but it’s been it’s been really eye opening over the last couple of years of things that that we’ve been able to put together from an analytic standpoint like Brian mentioned the the emissions scorecard that’s something that never crossed my mind and Brian be prepared. I got a couple of questions for you after the webinar on that, but it’s Data can be overwhelming but again. you know, it’s it’s we try to do it by the the kiss principle, you know, keep it simple stupid and focus on what’s actually important and we’ve built a number of dashboards reports everything else that you know, 60 days after we build them we realize that yeah, this is this is creating more confusion than anything so we scrap that and go a different way. So you have to be able to adapt, you know, pretty quickly and But that connected Fleet, you know, having the connection to the driver and to the systems and having those all work together. It’s a big undertaking but it’s it’s time and money. Well without a doubt it’s it’s made a huge difference for us. All right. Thanks. Thanks Brent Brian us. Sorry the same question with everything Fleet Advantage does it would seem that they that you work towards providing connected Fleet Solutions. One thing that that comes to mind from Brent slide is the phrase that I agnostic Solutions. Can you can you speak to how a fleet might might go after healthy might go about becoming connected and if that idea of agnostics solutions helps helps make that happen more more cost effectively and more productivity with more productivity improvements for Fleet operations. Sure, so I think that you know Brent just did a great job explaining how many inputs are coming in but they keep on evolving. Right? So one of the things that he touched on was even a connected trailer. So we started off if you think back. 15 20 years ago with what we described as a GPS or a single tracker just to see where the piece of equipment was. Now you can understand what the what the coolant temperature is. You know where you are. If there’s any check engine codes, you can move your way back. You can understand the air pressure of the tires. We’ve even got to the point where you can understand the temperature of the wheel ends, right? If you’re having wheel and failures, you can move back through the trailer you can understand the the reefer temperature and um temperature changes as doors open and as routes go through and that’s all great. But one of the challenges is if you think about that evolution of the technology Those were in many times different companies that came up with them. Right? So it’s not one company where you go to One dashboard. You have these multiple dashboards and multiple inputs and I think when I think of agnostic I think of let’s understand. What is the right? Data input what’s the right company to use and to make sure that as the data comes in? It’s a seamless as possible. And even though you may like us, you know company X Y and Z if you can have one or two fewer data inputs, and it comes in cleaner by using company one, two three. Right forget about the brand name of the company and use the one that makes the most sense as we integrate our data. Anybody can get you Road speed anybody can get you coolant temperature now which one fits into your system? You know what Fleet Advantage we tout ourselves as being OEM agnostic and Technology agnostic because what we’re looking at is what is the right piece of equipment and what’s the right technology packages you try to pull all that together. For our customers based on their needs right and then you know, we do the best very best we can to try to simplify that and get that into and do some of the same work that Brent’s doing to you know, smooth it out for his organization. We’re taking those inputs and trying to feed them back out in a way that they can become actionable with it. And that’s what we’re all trying to do. We’re trying to be actionable with the data that we have coming in. All right actionable rather than drowned by data. Thanks, very yes. Thanks very much for your insights. Brian and Brad at this point we’re going to switch over to questions. We have some time remaining to answer some of the questions that came in during the presentation and I’ll be throwing those out to to Brent and Brian. Let’s get started here. We have one question here. What is the most what are the most important pieces of data? You would utilize? What when you look at look at the look at your full picture? So I can jump in there for my perspective or I always I always start with what is every company say the most important thing is safety. Right? So if you truly starting with safety if I have a bandwidth challenge where I can only take in so much data. I want to make sure that I’m taking in the data that’s going to drive my safety score down and and put us as the safest company out in the road. Right? So when I think about that, I think about possibly air pressure monitoring that’s on trucks I think about Making sure that there’s certain codes that are being pushed out by the truck. I break code or you know a throttle position code where you may have it will negatively affect the driver’s ability to react on the road. I would consume that data and make that as actionable as I can first and work towards your cost reduction and your driver benefit second. Once we make sure we’re safe on the road then work towards the rest of the data coming in. All right. Thanks. Thanks Brian. And for listening out to Brent, but Brian you can feel free to add add to it as well. Are you seeing better data sharing and Integrations among your technology vendors and service providers and how are these Partnerships helping to reduce costs for fleets and I would just add how how many partners can can become integrated and still still make the result effective. And we’re definitely seeing the I wouldn’t say more. Necessarily more cooperation between vendors but vendors are making it more accessible and and easier to integrate with other other providers and other systems, you know with a using apis we can pull a lot of data we can use it to push data to to other other areas within our Network where that’s all combined and and pulled together. For example with best pass, you know best pass offers an API that we took advantage of that as soon as we as soon as we made the move over to to their system and we don’t our our users never log into the best passport. They do it directly from from our TMS by assigning the transponder to the truck. It automatically goes out and updates the best passage system. And you know if we have to change the transponder out or take a tractor out of service. It’s automated. And so it can it can be multifaceted. You know you you can actually reduce. The amount of manual entry and manual work that goes into something as well. But from a data perspective, you know, most telematics providers like like Brian mentioned. I mean you can anybody can give you that information. It’s what you can do with it from there. So we are seeing the amount of data increased. I wouldn’t say as much cooperation between the vendors but making it easier for the the end user to pull that that information together from other providers as well. And throw this one to you Brian. And I know it’s affected by a lot of variables. But what would you say is the expected payback period for electric vehicle over over the most advanced clean diesel truck that’s out there now. How great question I really think it comes down to the vocation of the vehicle. So if you think about a yard truck today. that’s You know running 2021 hours you could control the charging on site. You don’t have to work worry about any range. And you look at the reduction in. M&R costs as well as fuel cost yard trucks are pretty close to a break even today. And as you move away from the Hub and you go to local delivery. And you’re still going to be able to return them low mileage less than a hundred miles a day. You know, you’re probably gonna break even in the next two to three years as you start moving out to Regional and Long Haul. We’re probably still Oh six or seven or eight years away from where? Electric technology is gonna pass diesel technology from a cost standpoint. Right and it’s it’s really about how they’re going to be able to add additional range. And I even hate to talk just electric when I talk about alternative Vehicles because I think what we’re seeing is while electric is playing a key role now, we could end up with hydrogen or shift back to natural gas. But when you talk about Electric anything that’s longer than local delivery. We’re still A 10 years away from them breaking from a cost standpoint. Okay. And this one this went over to you Brent. Will root optimization systems work work for HazMat carriers to help them, you know to develop the most efficient roots. There are some out there that do, you know, that’s that’s one of the the caveats that would need to be addressed with a particular provider. But there are a number of them out there that that do take Hazmat routing into consideration. You know, it looks at the load type to determine whether or not it is has met but yes, it’s it’s definitely a thing and it’s definitely out there. you know not all vendors have it but but it does exist and it’s it’s from I’ve never used one of the Hazmat Hazmat routing systems were from what I understand. I know several that have and they’ve never had any any issues whatsoever with it. So it is definitely a thing. Okay, and Brett while I have you you’re told management provider that do they cover tolls and All 48 states? before Decker will not not all 48 states have tolls but they do have nationwide coverage best pass does for any state that has tolls best pass has them has them covered so there are One Stop Shop for tolls. All right. Sounds great. And one for you Brian get close to wrap up here. How about trailer tracking? What costs do the is having one of those systems help reduce. I’m glad you brought that up. It was in one of the slides in the bullet points for me. This is one of the biggest bangs for your buck you can get. The cost is very low. It can be single dollars per unit per month. Right and when you think about walking on to any of these large yards whether you’re at a customer or a trucking company, that’s moving it. It’s not uncommon to see hundreds of trailers. Each of those trailers are at a different spot in their their work that they’re doing. Some of them are loaded. Some of them are waiting for maintenance. Some of them are, you know are in there just waiting for their their next up in line and when you think of the cost of a trailer For a dry trailer today, we could be around anywhere between 60 and 70 thousand dollars, which is a far cry from the $25,000. We were at just 10 years ago. So making sure that you know where these trailers are. You’re not allowing them to sit if they get shifted over to a customer, you know where they’re at, right and being able to utilize those similar to attractor. It is just crucial right the amount of money that we put into trailers. It’s no longer the small cost associated with the shipping. It’s a 50 to 60 to 70,000 asset. If it’s refrigerated like Brent, I think you referenced, you know, 50 or more percent of yours was refrigerated. Those are $100,000 assets and making sure you’re thinking of them like that and not just the next trailer that’s up as crucially important. But the tracking is very very cheap, right? It’s it’s typically a lot lower than what it costs to track a tractor and you know, if you don’t know where your trailers are you wasting money. All right, and I would add to that as well Brian you mentioned utilization there. I’m sorry, baby. Go ahead. No you go ahead. So I was gonna say in in addition to what to what you mentioned on utilization Brian. We have you know shippers that have trailer pools where we drop 15 to 25 trailers at their location that they load as needed. We’ve seen instances using trailer tracking where we realize that and we’re all in X number of loads from per week out of that that facility but we’re doing it on the same seven trailers and the other 18 are just sitting so, you know that that gives you some insight there as well. We’ve also seen instances where you know, our trainer was emptied two hours after we after we dropped it, but four days later, it’s loaded again and the reefer’s back on because they’re using it for storage. So it’s it’s definitely a cost saver. Brian that’s all the time we have for anyone for anyone who Did not have their question answered will be following up by email to answer those questions individually. We hope you enjoyed today’s webinar want to again. Thank Brian and Brent and our sponsor best pass for for today’s presentation. The webinar will be available on demand on the heavy-duty Trucking website at Trucking info.com forward slash webinar. Thank you and have a great day.

Read Transcript

How to Drive Down the Costs of Running a Fleet

Heavy Duty Trucking hosted this webinar in January 2023 with moderator David Cullen and speakers Brent Ellis, VP of Business Systems & Processes at Decker Truck Line, and Brian Antonellis, CVP, Senior Vice President of Fleet Operations at Fleet Advantage.

You’ll learn key takeaways from each speaker on how to keep costs down, including:

- Route optimizations

- Asset management technology

- Toll management